In the 1960s, around the model of "import-processing-export", Taiwan formed a processing export economic system with the theme of light and textile industry, and labor-intensive industries were the main theme of Taiwan's economy in this period. But with the outbreak of the oil crisis in 1973, the global economy fell into recession. At that time, Sun Yunyi, the new "minister of economy", believed that only by moving away from labor-intensive and technology-intensive industries could Taiwan's economy be completely transformed.

Therefore, in 1973, Sun Yunkun proposed to follow the example of South Korea's "Science and Technology Research Institute" and set up a semi-official industrial technology research institute, which is mainly funded by the authorities. As an R & D institution, ITRI carries out R & D projects, and then ITRI will provide technology to industrial companies to achieve commercial development.

China's Taiwan Semiconductor Industry coming out of ITRI

In 1974, ITRI set up an organization to develop semiconductor technology, the Electronic Research and Services Organization (ERSO). Through the research and development of important technologies and technology transfer, ERSO contributed to the start of Taiwan semiconductors in China. According to the book The New Argonauts, in 1976, ERSO signed a five-year technology transfer agreement with RCA of the United States. The agreement emphasized training and technology transfer, so ERSO sent a team of 37 engineers to the RCA plant in the United States for a year of intensive training in integrated circuit design and manufacturing. The agreement also states that RCA will transfer all technology and design and process improvements for the manufacture of CMOS devices, buy back a certain number of wafers produced by the plant, and provide information about product applications. Later, the 32-member team formed the leading core of Taiwan's integrated circuit industry in the coming decades.

The RCA project has the following two far-reaching effects on the development of integrated circuits and other high-tech industries in Taiwan. For the first time, ERSO absorbed the knowledge of manufacturing technology and IC business operations. The second is the application of ERSO engineers to design and research and development.

After a year of training, in 1977, Taiwan established its first IC demonstration factory, which is the foundation of Taiwan's semiconductor industry. In 1980, United Microelectronics Corp broke away from the ITRI and became the first integrated circuit company in Taiwan, and a large number of people involved in the RCA project joined United Microelectronics Corp. Six years later, Taiwan Semiconductor Manufacturing Co Ltd also came out of the ITRI. Taiwan Semiconductor Manufacturing Co Ltd promoted the development of six-inch semiconductor wafers through ERSO professionals and ERSO processing technology. In 1993, ITRI gave rise to the world's advanced. At that time, the 8-inch wafers produced by the world's advanced production promoted the upgrading of the semiconductor industry.

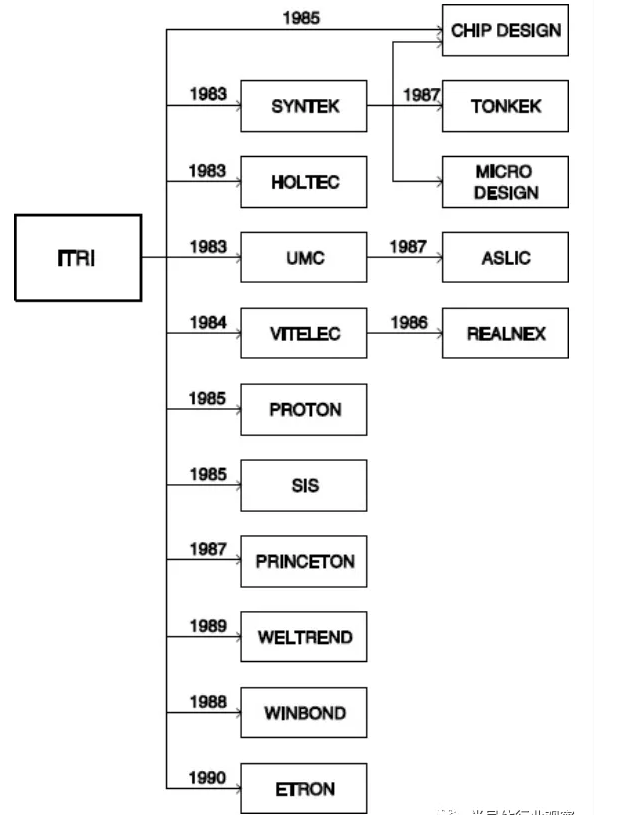

At the same time, ITRI turned its attention to IC design. ITRI established the Integrated Circuit Common Design Center (CDC) in 1985 to encourage emerging design companies. ERSO also provides nine Taiwan universities with computer-aided design tools and logical unit libraries to encourage the establishment of IC design programs. From 1983 to 1990, it spun off more than a dozen companies with IC design capabilities, including Huabang Electronics, which was founded in 1987, when a team of more than 200 people from ITRI joined Huabang Power and locked its product line in logical IC.

ITRI has played a great role in promoting the development of semiconductors in Taiwan. In the 2013 issue of 21st Century Manufacturing:The Role of the Manufacturing Extension Partnership Program, there is a picture that outlines the role of ITRI in promoting integrated circuit design.

The role of ITRI in promoting integrated circuit design. Source: Liu Zhongyuan, ITRI, "the role of the Government in the Development of High-tech Industry: a case study of Semiconductor Industry in Taiwan, China", Technovation,13 (5), 1983. )

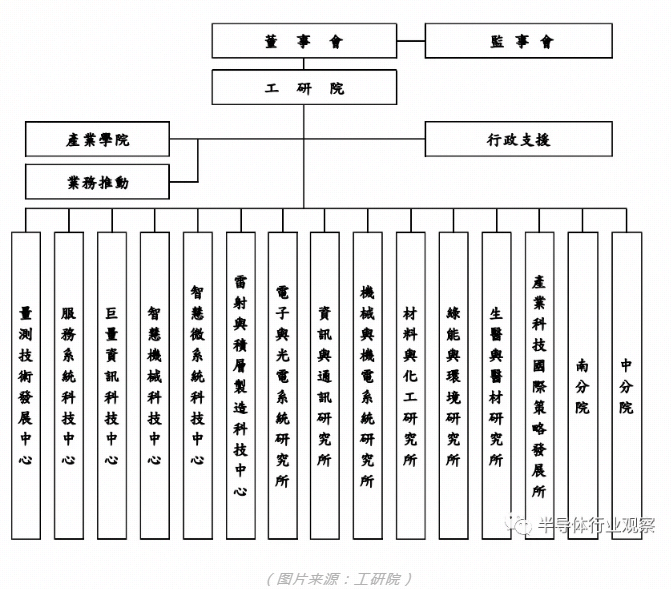

Up to now, judging from the composition of ITRI, according to its business scope, ITRI has established a total of 6 research institutes and 7 science and technology centers, as well as other units such as industrial college, southern branch, central branch, business promotion and administrative resources (such as organization chart).

Among them, according to the plan previously released by ITRI, ITRI plans to internationalize the Nangang IC Design Park, and ITRI plans to stimulate the establishment of SoC/IC start-ups with energy through strategic alliances, and expand the depth and breadth of technology in Taiwan's SoC/IC field, so as to promote the vigorous development of Taiwan's IC design industry.

The output of talents from ITRI

Taiwan Industrial Research Institute of China has not only promoted the birth of many semiconductor enterprises, but also created a lot of semiconductor talents, which are also the basis for the continuous development of Taiwan semiconductors in China.

In the early days of the establishment of ITRI, there was a lack of relevant talents in Taiwan. Combined with the market situation at that time, ITRI took measures to actively attract and train talents to promote the development of the industry. In the 1990s, with the arrival of globalization, the brain drain of ITRI is serious. In view of this situation, ITRI launched a talent balance policy, which not only encourages the transfer of talents to enterprises, but also implements some policies to attract more talents at home and abroad to join.

According to the article "from intellectual Cradle to Industrial engine: a brief Analysis of the Talent training and Application Policy of Taiwan Industrial Technology Research Institute of China", these policies include the launch of forward-looking research projects and related research awards; cooperate with international famous research institutes to provide employees with opportunities for further study and exchange, but also invite famous experts to exchange training; go to universities with a concentration of talents and take the initiative to invite talents to join.

After entering the 21st century, Chinese mainland has a great demand for semiconductor talents. because Chinese mainland has advantages in salary and other aspects, it has prompted some talents to come to the mainland from Taiwan. In view of this situation, ITRI has also made plans in four aspects in recent years, including actively recruiting international talents, cultivating and attracting software and system talents, strengthening the retention mechanism, and strengthening employee care.

According to relevant statistics, by 2016, ITRI has exported a total of 18000 people from all walks of life, and many of them have become senior executives or business executives in the science and technology park. According to a report released by ITRI in 2019, at present, ITRI has a total of 6164 R & D and management talents, including 3646 masters and 1424 doctors.

The investment direction of ITRI in the past two years

Since 1973, the semiconductor industry in Taiwan has become an important part of the global semiconductor industry chain. In the annual budget of ITRI, the semiconductor industry has always been regarded as a part of the existing industry and an industry that needs to constantly improve its competitiveness.

According to the annual budget of ITRI in 2018, chip design and semiconductor foresight technologies that meet the requirements of the Internet of things (IoT) will be developed for the project, including (1) artificial intelligence processing chips, artificial intelligence model development tools and environments, and NVM neural computing chips; (2) IoT hardware encryption protection chips, chip LiDAR (3) develop heterogeneous integrated design platform, heterogeneous integrated packaging technology, heterogeneous micro-component system assembly, multi-functional heterogeneous component detection technology. The chip, sub-system and system prototype products are connected in an one-stop way to construct the ecological environment of IoT industry in Taiwan.

In addition, in terms of electronic components, ITRI also pointed out that the rise of 5G communications and the Internet of things needs to focus on high-value innovative applications. To this end, ITRI will develop millimeter wave substrate, wide energy gap wafer materials, high reliability RF semiconductor packaging technology, flexible high dielectric composite ceramic wafer technology and millimeter wave communication assembly technology.

In the budget report of ITRI in 2019, the importance of chips and 5G components in the field of Internet of things was put forward again. During the year, in addition to continuing the plan developed in 2018, ITRI also pointed out the role of semiconductors in the medical and industrial fields.

Future development

In order to create a better future, ITRI has developed the Technology Strategy and Roadmap 2030, in which the development of ICT enabling technologies has been strengthened and focuses on three application areas: smart living, quality health and sustainable environment. Among them, ICT is an important factor in supporting multiple applications in the 2030 technology strategy and roadmap. To this end, ITRI has turned to artificial intelligence, semiconductors, communications, network security and cloud technology to promote technological breakthroughs in the above three application areas.

In terms of intelligent life, according to the annual business focus released by the Industrial Research Institute, machinery is the basis of manufacturing, and the current situation of related industries is transforming from low-cost manufacturing to innovative advanced manufacturing. The key research of advanced manufacturing includes intelligent manufacturing, micro-nano and laser, micro-electromechanical system technology development, nano-optoelectronic, panel and soft electricity process equipment and precision chemistry, soft substrate and optical film manufacturing. It is expected to help promote the development of semiconductor equipment, advanced process equipment, advanced (information, energy, green) materials and other related industries in Taiwan.

In terms of strengthening the semiconductor industry, ITRI proposed to assist the integration of 3D integrated circuit industry (in 2008, ITRI organized an advanced stacking system technology and application alliance, developed 3D integrated circuit technology, which is based on the stacking of multiple thin IC and the interconnection of straight-through area arrays between them), and developed process interface specifications. The product target will be DRAM, Flash and CIS (CMOS image sensor) applications. And realize the application of high-speed, high-density and low energy-consuming products to create a new semiconductor industry.

According to the annual report issued by the Industrial Research Institute, it has layout plans in semiconductor equipment, advanced packaging and other aspects, and has made certain achievements in some fields. (the following is the layout and achievements of some ITRI.)

Specifically, in terms of semiconductor equipment, ITRI pointed out that with the continuous development of manufacturing, the demand for high-precision maskless lithography machines is increasing. Although semiconductor equipment manufacturers have introduced such machines from abroad, there is little knowledge of their technical details, which affects the follow-up research and development. In order to establish the core technology of Taiwan's own maskless lithography machine, ITRI has developed the key technology for laser direct imaging maskless lithography machine.

In addition, metal organic chemical vapor deposition (MOCVD) epitaxy equipment is also a key processing component in the optoelectronic semiconductor industry. The traditional epitaxial process takes longer to set and adjust the process parameters. ITRI uses digital technology instead of the traditional manual adjustment, which can quickly determine the best parameters and shorten the product development cycle and listing schedule. The technology further integrates MOCVD hardware with CyberEpi software, so the industry can further control processes and equipment.

In the detection of the next generation semiconductor technology, the advanced semiconductor technology has reached the technology node of 7 nm or less; however, the existing film thickness and key size inspection technology has reached the detection limit. ITRI is developing X-ray metrology technology that can provide subnanoscale high resolution. This allows online measurement of key dimensions in the process of 7 nm,5 nm and 3 nm technology nodes.

According to media reports in Taiwan, last year, ITRI also cooperated with Qunchuang Optoelectronics to transform its existing panel production line into competitive panel-level fan-out packaging applications, cutting into the next generation wafer packaging opportunities to solve the dilemma that the semiconductor wafer front process continues to shrink, and the wiring level of the printed circuit board loaded with the wafer at the back end is still about 20 microns, and can provide high analytical wire capacity of less than 2 microns. High production efficiency and make good use of the existing production line equipment. It is reported that ITRI has cooperated with Qunchuang Optoelectronics to convert its existing 3.5-generation panel production line into panel-level fan-out wafer packaging applications, which, in addition to improving the utilization of existing production lines, has more advantages in terms of capital expenditure. in the future, we can cut into the supply chain of medium-and high-level packaging products, rush for packaging factory orders, and create high value with innovative technology.

In addition, a few days ago, the ITRI also published the world's first "layered 3D Circuit Technology", which has been introduced into Quanta computers, a large manufacturer of notebook computers around the world. the use of glass, ceramic, metal and other materials to make three-dimensional multi-layer circuits with a line width of only 15 μ m (micron) will help 3C products to meet the high-speed requirements of 5G.

According to a report from Kuiheng, in May this year, the ITRI said that Taiwan's semiconductor industry is expected to continue to grow this year, with an estimated output value of 2.8 trillion yuan, an annual increase of 5.7%, which is better than the global performance. ITRI believes that the positive impact on Taiwan's semiconductor industry this year includes multiple applications such as AI, 5G, automotive and the Internet of things, coupled with the trend of work at home driven by the epidemic, stimulating the production capacity of advanced processes, and a substantial increase in shipments of related IC, including temperature sensors and respirator chips. At the same time, ITRI also stressed that the key successful experience of the semiconductor industry in Taiwan is to take the science park as the core driving role and form a complete upstream, midstream and downstream science and technology cluster. Therefore, we should continue to make good use of the advantages of industrial clustering, focus on the next generation of innovative products and application services, and promote the pluralistic development of the industry.

Edit | Eric