Abstract

Tesla, Inc. (TSLA.US) held his first Battery Day on September 22nd, officially announced the plan of home-made battery, and demonstrated Tesla, Inc. 's significant advantages in battery research from the three dimensions of performance, cost and expenditure. The new battery technology proposed on Battery Day is in line with expectations, and the battery capacity planning also demonstrates Tesla, Inc. 's confidence in the future industry and company development.

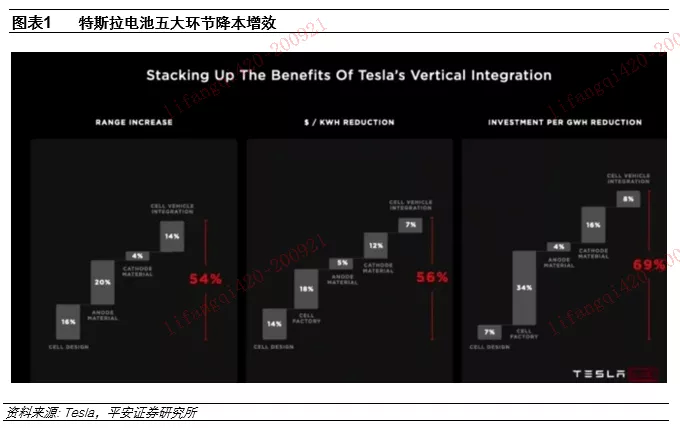

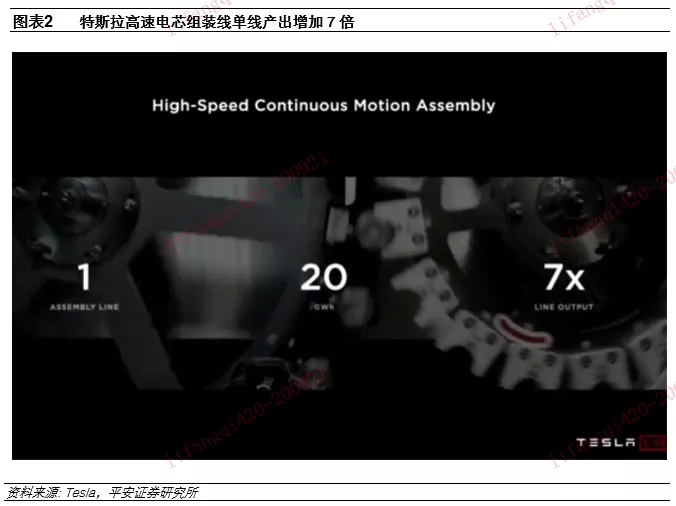

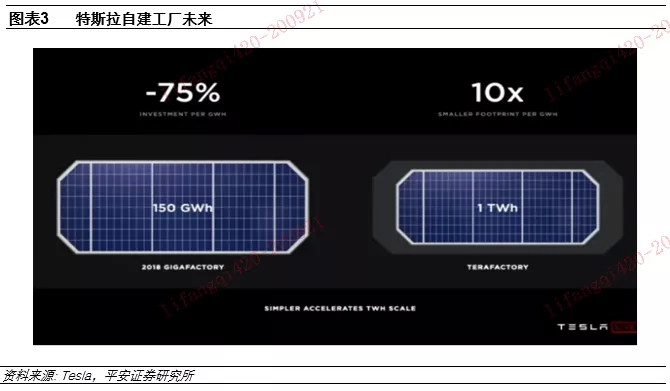

Five major links to reduce costs and increase efficiency, the prelude to self-built batteries.This Battery Day Tesla, Inc. put forward the vision of the next generation battery in five aspects: battery design, battery factory, negative electrode material, cathode material and the integration of battery and car body. Tesla, Inc. is expected to increase battery mileage by 54%, reduce battery manufacturing costs by 56%, and reduce unit investment costs by 69%. In terms of increasing mileage, Tesla, Inc. expects the potential of negative materials to be the greatest in the future (- 20%); in terms of reducing production costs, Tesla, Inc. expects that self-built battery factories have the greatest potential (- 18%); and in terms of reducing investment costs, self-built battery plants are expected to be the biggest contributors (- 34%). Tesla, Inc. optimized and expanded the whole process of the self-built battery factory: 1) using dry electrode process to simplify the production process and improve the production speed; 2) high-speed cell assembly production line to achieve continuous assembly processing; to achieve 20GWh on a single assembly line, a 7-fold increase in single-line output; 3) into a capacitive link, reducing 75% of the complex process and 86% of the cost through the management of the electronic system. Generally speaking, Tesla, Inc. 's self-built factory Terafactory will greatly reduce production capacity investment and simplify the production process in the future. The company aims to achieve 100GWh battery capacity in 2022 and 3TWh in 2030. In addition to self-use, the remaining capacity can be supplied.

Process upgrade:Large core + electrodeless ear + dry electrode. Tesla, Inc. 's battery model continues to be upgraded to 4680 this time. Depending on the upgrade of this cell design (large cell + electrodeless ear), the battery energy is expected to increase by 5 times, the range by 16%, and the power by 6 times. This design scheme can reduce the battery cost by 14%. The electrodeless ear electrode process mainly improves the performance of the battery from three aspects: 1) shortening the current movement path to reduce the internal resistance; 2) significantly reducing the current offset phenomenon; 3) heat generation and heat dissipation capacity has been significantly improved. Musk said the results of the experiment were satisfactory as to the subversive move to remove the extreme ears. The 4680 battery will be produced in a pilot production line at the Fremont plant with the current capacity of 1GWh, followed by plans to reach 2GWh, mass production in 2022, and further expansion to the scale of 200GWh in the future. In terms of dry electrode technology, Musk said that the previous dry electrode scheme was optimized and the optimal scheme was obtained. it is currently in the state of close

to

working and is not yet fully mature. In terms of automotive electrical integration, Tesla, Inc. adopts the scheme of structured battery, which is built directly into the car structure, making a better combination of the battery and the car body. It is expected to lose 10% of the weight, reduce 370 parts and speed up production. At the same time, it may bring a 14% increase in battery life. Considering the optimization of body process and Pack process, the production cost can be reduced by another 7%.

High nickel cobalt-free cathode + silicon negative electrode, the material system is in line with expectations.In terms of cathode materials, Tesla, Inc. explored three ideas to give up cobalt materials: 1) using iron in cathode materials, used in low and medium range passenger cars and energy storage, focusing on long cycle life; 2) using nickel and manganese materials, mainly used in passenger cars, mainly long range range; and 3) high nickel materials, used in Cybertruck pickups and Semi trucks, focusing on high energy density. In terms of negative materials, Musk said that through the redesign of raw materials, high elastic materials and coating materials to achieve and solve the expansion problem of silicon materials, the final realization of the cost per KWh is only $1.20, while increasing the battery mileage by 20% and contributing 5% to the cost reduction of the battery. Tesla, Inc. plans to build a North American positive production base with both positive and upstream metal links, reducing transportation costs by 80%, engineering investment by 66% and production costs by 76%. In terms of nickel resources, metal nickel is used instead of nickel sulfate as the input of raw materials to reduce costs. In terms of lithium resources, it is planned to extract lithium directly from minerals. In terms of battery recycling, Tesla, Inc. plans to start a pilot battery life cycle recycling pilot next quarter to further reduce the cost of raw materials.

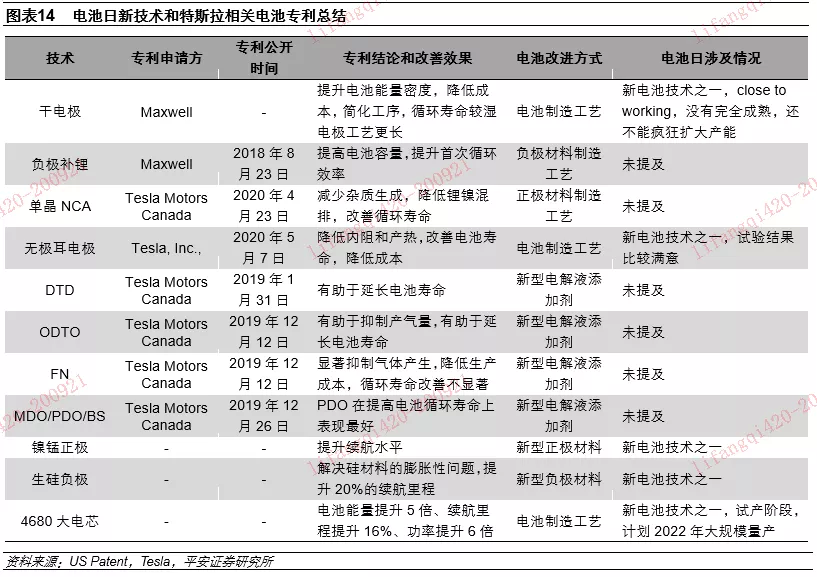

Battery Day Summary:The new battery has not yet entered the pace of mass production, and a number of patents have not been mentioned. In terms of materials, on the whole, the material system proposed by Tesla, Inc. has not deviated from the mainstream technical route of the current industry, and there is no innovative material system. At present, Tesla, Inc. has been in the forefront of the market in the industrial application of silicon negative electrode, and has put forward a better solution to the problem of silicon expansion. If it can effectively improve the mileage of mass-produced models, it will be expected to accelerate a new round of changes in the industry. In terms of technology, large cylindrical cells, electrodeless electrodes and dry electrodes belong to Tesla, Inc. 's unique technical route, but it still takes some time for large-scale mass production, and the current technology is hardly mature. In addition, the technologies, materials and process plans involved in many previous patents, such as lithium anode supplement, single crystal NCA and new additives, were not mentioned on this Battery Day, and subversive battery technologies such as solid-state batteries and million-mile batteries did not become the topic of this event. In terms of car sales, the company expects 20-year-on-year sales to grow by 30% and 40%. In terms of new models: 1) at present, Cybertruck has received more than 600000 orders, and sales are expected to reach 250000 to 300000 per year; 2) the company announced that the Plaid version of Model

S will be delivered by the end of 2021, with a range of more than 836km and 100km acceleration in 2s; 3) Tesla, Inc. is expected to use all the new battery technology to produce a self-driving car priced at US $25000 in 2023.

Investment advice:Ping an Securities believes that Tesla, Inc. 's home-made battery innovation ideas are more for the production process links, and these technical links are not yet fully mature, and there is still some time before large-scale mass production; in terms of materials, the core electrochemical system is hardly subverted and does not exceed the R & D scope of mainstream battery enterprises. Global first-line battery manufacturers are still able to maintain sufficient competitiveness by virtue of their strong R & D strength. Tesla, Inc. showed full confidence in the future development of new energy vehicles in this battery day. Ping an Securities believes that under the guidance of industry pioneers, the process of global electrification transformation is unstoppable, and Chinese enterprises are expected to fully benefit.

Risk Tips:1) the risk that the commercial application of the new technology is not as expected: the final effect and commercial application of many technologies in the patent still need to be further observed. if the commercial application is not as expected, it will affect the mass production rhythm of the new battery. 2) the risk that the policy strength is not as strong as expected: if the support of domestic and foreign policies for new energy vehicles is softened or changed, resulting in the introduction of policies less than expected, it will significantly affect the overall scale of the new energy vehicle market. 3) the risk of consumer trust caused by electric vehicle spontaneous combustion accidents: new energy vehicle spontaneous combustion accidents occur frequently, and the high nickel battery system adopted by Tesla, Inc. is a big test for the safety of the product itself. If the spontaneous combustion incident is not effectively controlled, it may lead to a crisis of trust among consumers, which will have a negative impact on product sales. 4) the risk of technological route change: new energy vehicles are still in a period of rapid technological change, and Tesla, Inc. leads the industry in innovation. If the next generation technology industrialization process exceeds expectations, it will have a significant impact on the existing industry pattern, and the early investment recovery capacity will be lower than expected.

1. five major links to reduce costs and increase efficiency, and the prelude to building self-built batteries

Improve battery production efficiency and greatly reduce manufacturing costs. This Battery Day Tesla, Inc. put forward the vision of the next generation battery in five aspects: battery design, battery factory, negative electrode material, cathode material and the integration of battery and car body. Tesla, Inc. is expected to increase battery mileage by 54%, reduce battery manufacturing costs by 56%, and reduce unit investment costs by 69%.

The self-built battery factory is the main force to reduce the cost, and the key to improve the battery life level lies in the negative electrode. In the process of promotion]In terms of mileage, Tesla, Inc. expects the greatest potential of anode materials in the future (- 20%), followed by cell design (- 16%). In terms of reducing production costs, Tesla, Inc. expects that the self-built battery factory has the greatest potential (- 18%). Followed by cell design (- 14%) and cathode materials (- 12%); in reducing investment costs, self-built battery plants are expected to be the largest contributor (- 34%).

Tesla, Inc. optimized and expanded the whole process of the self-built battery factory:

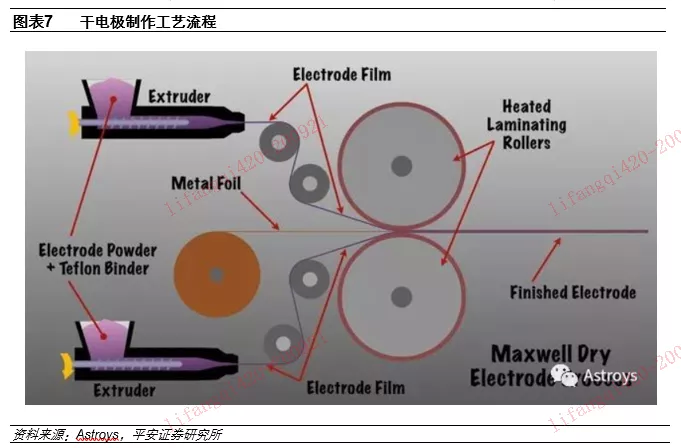

1) adopt dry electrode process (described in detail later) to simplify the production process and improve the production speed.

2) High-speed cell assembly production line to achieve continuous assembly processing; 20GWh on a single assembly line (the output per line is increased by 7 times); all production lines are integrated and automated, and the production line is more intelligent and efficient.

3) reduce 75% of complex processes and 86% of costs through the management of electronic systems.

Generally speaking, Tesla, Inc. 's self-built factory Terafactory will greatly reduce production capacity investment and simplify the production process in the future. In the future, it will be able to accommodate 1TWh's battery capacity in smaller factory space, with a 75 per cent reduction in investment per GWh (compared to Gigafactory with 150GWh capacity). The company aims to achieve 100GWh battery capacity in 2022 and 3TWh in 2030. In addition to self-use, the remaining capacity can be supplied.

2. Process upgrade: large core + electrodeless ear + dry electrode

1865 to 4680, large cell + electrodeless ear

Battery upgrade triple jump. Tesla, Inc. first used 1865 cylindrical cells (18 for diameter and 65 for length) in 2008. In 2017, he first used 2170 in Model

3, and the energy of the cell increased by 50%. The battery model continues to be upgraded to 4680, and with the upgrade of this cell design (large cell + electrodeless ear), the battery energy is expected to increase by 5 times, the mileage by 16%, and the power by 6 times. this design can reduce battery costs by 14%.

Improving battery performance and solving heat generation problems give birth to electrodeless ear technology. In the process of further increasing the diameter of the battery, the expansion of the volume has brought a more serious heat dissipation problem. Tesla, Inc. 's way to solve this problem is to remove the traditional polar ear structure of the battery. According to Tesla, Inc. 's relevant patents, the manufacturing process of electrodeless ear electrode cell partially or completely cancels the traditional electrode ear, and adds a conductive coating at the edge of the positive or negative electrode, so that the conductive coating is in direct contact with the battery end cover, and the current reaches the battery external circuit through the conductive coating and the battery shell. Theoretically speaking, the electrodeless ear electrode process mainly improves the performance of the battery from three aspects:

1) the current moving path is shortened and the internal resistance is reduced. The traditional battery design structure determines that in order for electrochemical reaction to occur, the current should move along the length of the electrode, and the distance of movement is related to the position of the electrode ear (the middle or both ends of the electrode). The electrodeless ear electrode process provides a more consistent electrical contact mode between the electrode current collector and the inner surface of the battery end cover, so that the maximum distance of the current movement becomes the height of the electrode rather than the length. The height of the general electrode is 5% of the length, so the internal resistance of the electrodeless electrode can be reduced by 5-20 times in the electrochemical cycle.

2) significantly reduce the phenomenon of current shift. The current offset phenomenon means that some areas of the electrode pass through more or less current than others; without considering other factors, the current will approach the electrode ear along the path with the lowest internal resistance on the electrode. in this way, a large overpotential will be generated locally, resulting in unnecessary chemical reactions and reducing battery life. The electrodeless ear electrode process reduces the internal resistance, the current path is shorter and the distribution is more balanced, so it can avoid the generation of overpotential and improve the battery life.

3) the capacity of heat production and heat dissipation has been significantly improved. In terms of heat production, the heat generated is also reduced due to the reduction of internal resistance. In terms of heat dissipation, the traditional electrode ear has only a very small contact area with the battery end cover, while the effective contact area between the conductive coating in the non-polar ear electrode and the battery end cover reaches 100%, and the increase of the contact area improves the heat dissipation capacity. further optimize battery performance and prolong cycle life.

The experimental results are satisfactory and the mass production plan is put on the agenda. For this subversive move to get rid of extreme ears, Musk said, "the process is very difficult, the engineering department has spent a lot of efforts and designed a lot of patents, and the results of the experiment are satisfactory." The 4680 battery will be produced in a pilot production line at the Fremont plant with the current capacity of 1GWh, followed by plans to reach 2GWh, mass production in 2022, and further expansion to the scale of 200GWh in the future.

2.2 the guess of dry electrode falls to the ground, and the application of lithium battery is not yet fully mature.

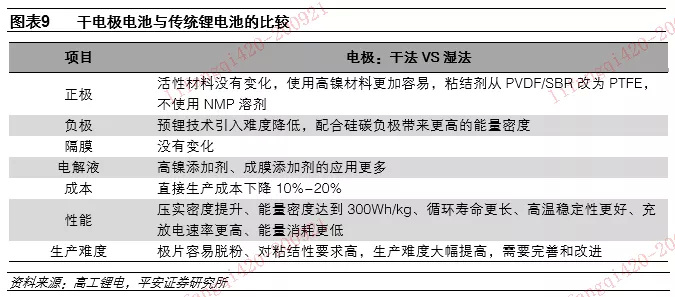

The difference between dry electrode battery and traditional battery is mainly reflected in the manufacturing process of the electrode. In traditional lithium battery manufacturing, the solvent NMP with adhesive material is mixed with negative or positive powder, and the paste is coated on the electrode collector and dried. The dry electrode technology does not use a solvent, but mixes a small amount (about 5-8%) of fine powdered PTFE adhesive with positive powder powder, and then forms a thin electrode material strip by extruding the cathode + adhesive powder through an extruder, and finally laminates the extruded electrode material onto the metal foil collector to form a finished electrode.

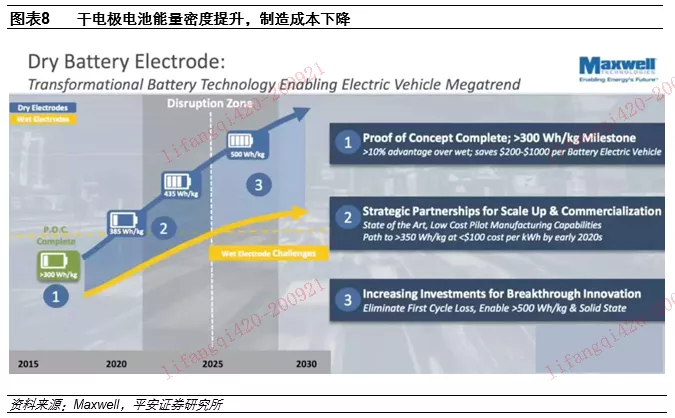

Tesla, Inc. 's dry electrode technology comes from the acquisition company Maxwell. Compared with the traditional wet process, dry electrode technology mainly has the following advantages:

The main results are as follows: 1) the compaction density is high, and it is more compatible with the material system of high nickel battery. Compared with the traditional process, the dry electrode itself has high compaction density, and this technology can apply active materials with higher energy density and higher liquid sensitivity, such as high nickel and silicon, to the production of electrode. it makes it easier to increase the energy density of the battery with less risk. At present, Maxwell has been able to achieve a cell energy density larger than 300Wh/kg by using dry electrode technology, which is more than 10% higher than the current wet electrode battery; it may reach 500Wh/kg in the future.

2) compared with the wet process, the cost is reduced by 10% 20% +. The dry electrode does not use toxic NMP solvent, which is more environmentally friendly, at the same time, it saves the production links such as coating and electrode drying, reduces the cost of materials and equipment, and simplifies the production process. If the cost reduction caused by the potential increase in energy density is taken into account, the dry electrode process will further reduce the cost. The current dry electrode process has reduced the cost of a bicycle by $20 to $1000; Maxwell is expected to achieve a cell energy density that exceeds that of 350Wh/kg in the early 1920s, corresponding to a manufacturing cost of less than $1000 / kWh.

3) other important performance improvements. It includes longer cycle life (twice as much as the wet process), better high temperature stability, higher charge and discharge rate (lower internal resistance of dry electrode), lower energy consumption and so on.

Dry electrode technology has been used in supercapacitors, but it is difficult to use lithium batteries. Maxwell is one of the few enterprises in the world to use dry electrode technology to produce supercapacitors, which has a mature commercial application case. The super capacitor positive and negative electrode materials all use activated carbon, the specific surface area is high, the expansion coefficient of the electrode is low, the requirement of adhesion is not high, and it is not difficult to use the dry electrode process, while the specific surface area of the commercial lithium battery positive and negative electrode material is small. the charge and discharge process is accompanied by volume expansion, so the electrode is easy to be powdered, so the adhesion is high, and the current dry electrode process is difficult to meet the production requirements.

The optimal scheme is obtained by process improvement, but the application of lithium battery is not yet fully mature. With regard to the current progress of dry electrode technology, Musk said, "this is a very complex process, and the actual operation is very difficult. Ping an Securities's dry electrode optimizes the previous dry electrode scheme (capacitor dry electrode), adding a lot of processes." a lot of experiments have been carried out and the optimal scheme has been obtained; compared with the traditional scheme, the dry electrode can achieve 10 times the simplified process. At present, it is in the state of close

to working, and it can finally achieve practical application, but it is not yet fully mature and cannot frantically expand production capacity. "

2.3 the battery is integrated with the car body, similar to the CTC technology in Ningde era

Promote the design of the integrated structure of automobile body in the future. The idea of integrated design includes two aspects: 1) in the pure body (non-battery) part, the processing of the whole body can be optimized, such as the integrated casting method adopted in the current Model

Y part of the body, and the integrated design can also be done in other parts of the vehicle in the future. 2) in the electric combination part of the car, on the one hand, the new battery package can be glued in a better way to make the structure more compact; on the other hand, the structured battery scheme (structural

battery) is adopted, the battery is directly built into the car structure, making a better combination of the battery and the car body, which is expected to lose 10% weight, reduce 370 parts and speed up production, and may lead to a 14% increase in battery life. Considering the optimization of body process and Pack process, the production cost can be reduced by another 7%.

Similar to the CTC of Ningde era, the two sides are expected to achieve cooperation in the future. Previously, at the China Automotive Blue Book Forum, Ningde Times put forward the technical solution of CTC, which integrates the core and chassis, and then integrates motor, electric control and vehicle high voltage such as DC/DC and OBC through innovative structures, and optimizes power distribution and reduces energy consumption through intelligent power domain controllers. The company stressed that CTC technology will enable the cost of new energy vehicles to compete directly with fuel vehicles, have more passenger space and improve chassis passability, and said that apart from the unnecessary weight and space occupied by castings, CTC technology can enable electric vehicles to have a range of at least 800km. The goal of Ningde era is to complete the technology by 2030. Ping an Securities believes that the two sides have reached a consensus on the integration of car and electricity to reduce spare parts, reduce body quality, improve the level of battery life and reduce costs, and is expected to achieve cooperative development and production in the integration and integration of car and electricity in the future.

3. High nickel cobalt-free cathode + silicon negative electrode, the material system meets the expectations.

3.1 three kinds of cathode material systems, cobalt-free is the goal

From a metal point of view, nickel has the highest energy density and the lowest cost, so battery manufacturing tends to use more nickel, while cobalt is used to stabilize the battery structure, but the cost is high. Tesla, Inc. pointed out that the very high level of nickel in the battery can make it possible for the battery to be completely cobalt-free and contribute 12% to the cost reduction. Tesla, Inc. explored three ways to give up cobalt materials:

1) Iron is used in cathode materials for low-and medium-range passenger cars and energy storage, focusing on long cycle life. In practical application, the domestic standard life-lasting version of Model

3 is expected to be switched to the lithium iron phosphate battery provided by Ningde era.

2) using nickel-manganese material, Tesla, Inc. thinks that 2ax-3Ni and 1ax-3mn are the better ratio, which is mainly used in passenger cars and long-range.

3) High nickel material, maximizing the amount of compressed cobalt, used in Cybertruck pick-up trucks and Semi trucks, focusing on high energy density.

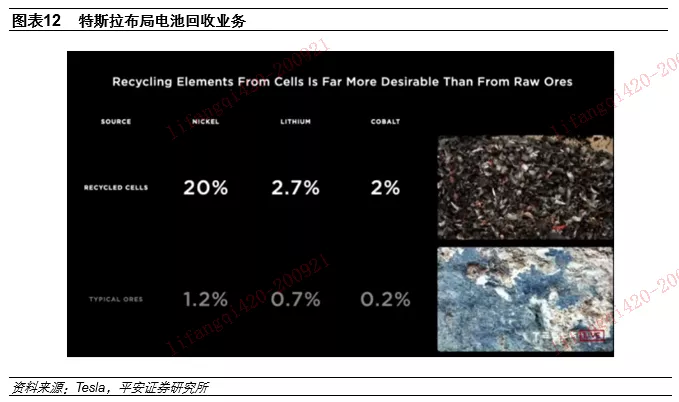

Layout of positive electrodes and upstream metal links to proceed with vertical integration. In terms of cathode materials, Tesla, Inc. plans to build a North American cathode production base, reducing transportation costs by 80%, engineering investment by 66% and production costs by 76%. In terms of nickel resources, use nickel instead of nickel sulfate as raw material input for production, reduce costs; in terms of lithium resources, obtain the right to exploit lithium mines in Nevada, and plan to directly extract lithium from minerals to reduce procurement costs. In terms of battery recycling, Tesla, Inc. plans to start a pilot battery life cycle recycling pilot next quarter to further reduce the cost of raw materials.

3.2 Silicon negative electrode leads the improvement of life, and the new process solves the expansion problem

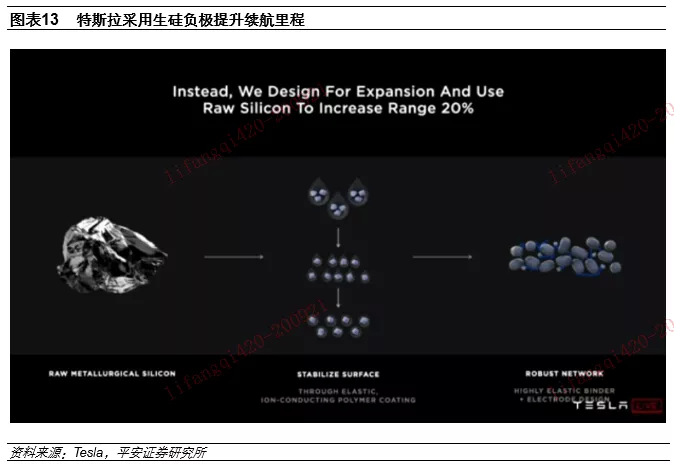

Negative silicon is very important, the earth is rich in silicon resources, compared with ordinary graphite, the energy storage effect is better, but the expansion of silicon will reach 4 times, and the current price is high, which is the main problem of commercial application.

Tesla, Inc. used silicon-carbon material as the negative electrode for a long time in his previous models, and this time he mentioned the silicon negative electrode. Musk said that through the redesign of raw materials, high elastic materials and coating materials to achieve and solve the expansion problem of silicon materials, the final cost is only $1.20 per KWh, while increasing the battery mileage by 20% and contributing 5% to the cost reduction of the battery.

4. Battery Daily Summary

4.1 the new battery has not yet entered the pace of mass production, and many patents have not been mentioned.

In terms of materials, on the whole, the material system proposed by Tesla, Inc. has not deviated from the mainstream technical route of the current industry, and there is no innovative material system, indicating that under the current environment, it is quite difficult to achieve technological breakthroughs at the material level, and enterprises are more likely to improve battery performance and reduce costs through changes in production processes. However, at present, Tesla, Inc. has been in the forefront of the market in the industrial application of silicon negative electrode, and has put forward a better solution to the problem of silicon expansion. If it can effectively improve the range of mass-produced models, it will be expected to accelerate a new round of changes in the industry.

In terms of technology, large cylindrical cells, electrodeless electrodes and dry electrodes belong to Tesla, Inc. 's unique technical route, but it still takes some time for large-scale mass production, and the current technology is hardly mature.

In addition, the technologies, materials and process plans involved in many previous patents, such as lithium anode supplement, single crystal NCA and new additives, were not mentioned on this Battery Day, and subversive battery technologies such as solid-state batteries and million-mile batteries did not become the topic of this event.

4.2 High growth in sales and further drop in the price of new models

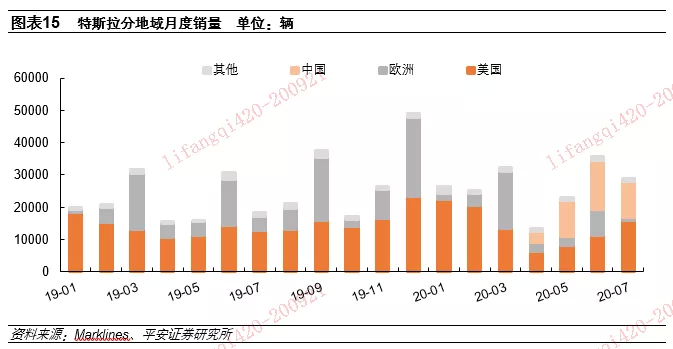

In terms of car sales, the company expects 20 years of year-on-year growth of 30% and 40%. Tesla, Inc. 's global sales increased by 50% to 360000 in 2019, and the company said at the Battery Day event that it is expected to achieve 30-40% sales growth this year. According to Marklines data, Tesla, Inc. sold a total of 185000 new cars worldwide from January to July 20 (actually more than 200000), an increase of 21% over the same period last year, including 98000 in the United States (+ 2% in the same period last year), 38000 in Europe (- 23% in the same period last year), 41000 in China (more than 60, 000 in China, according to the China Automobile Association) and 8600 others (+ 13% in the same period last year). If the 30% growth target is to be met, the company will have to sell an average of 50, 000 vehicles a month in the remaining five months of 20 years (at the level of December 19).

In terms of new models: 1) Cybertruck has received more than 600000 orders, and sales are expected to reach 250000 to 300000 per year; 2) the company announced that the Plaid version of Model

S will be delivered by the end of 2021, with a range of more than 836km and an acceleration of less than 2s. 3) Tesla, Inc. is expected to use all the technology of the new battery to produce a self-driving car with a price of only $25000 in 2023. Ping an Securities believes that the company will keep its initial price as low as possible to maintain a meagre profit, so as to gain more incremental customers. expand the stock of customers to build a larger ecosystem.

5. Investment suggestions

Ping an Securities believes that Tesla, Inc. 's home-made battery innovation ideas are more for the production process links, and these technical links are not yet fully mature, and there is still some time before large-scale mass production; in terms of materials, the core electrochemical system is hardly subverted and does not exceed the R & D scope of mainstream battery enterprises. Global first-line battery manufacturers are still able to maintain sufficient competitiveness by virtue of their strong R & D strength.

During this battery day, Tesla, Inc. showed full confidence in the future development of new energy vehicles, including battery capacity of 100GWh by 2022 and planned battery capacity of 3TWh by 2030. It is expected that the Shanghai plant will achieve an annual capacity plan of 1 million vehicles and launch a $25000 model based on new technology. Ping an Securities believes that under the guidance of industry pioneers, the process of global electrification transformation is unstoppable, and Chinese enterprises are expected to fully benefit.

6. Risk hint

1) the risk that the commercial application of the new technology is not as expected: the final effect and commercial application of many technologies in the patent still need to be further observed. if the commercial application is not as expected, it will affect the mass production rhythm of the new battery.

2) the risk that the policy strength is not as strong as expected: if the support of domestic and foreign policies for new energy vehicles is softened or changed, resulting in the introduction of policies less than expected, it will significantly affect the overall scale of the new energy vehicle market.

3) the risk of consumer trust caused by electric vehicle spontaneous combustion accidents: new energy vehicle spontaneous combustion accidents occur frequently, and the high nickel battery system adopted by Tesla, Inc. is a big test for the safety of the product itself. If the spontaneous combustion incident is not effectively controlled, it may lead to a crisis of trust among consumers, which will have a negative impact on product sales.

4) the risk of technological route change: new energy vehicles are still in a period of rapid technological change, and Tesla, Inc. leads the industry in innovation. If the next generation technology industrialization process exceeds expectations, it will have a significant impact on the existing industry pattern, and the early investment recovery capacity will be lower than expected.